future-oriented

The foundation

LC Automations was founded in 2014 after 30 years of consulting, technical assistance, and engineering for various Italian and European manufacturers.

It was not the need for fame and success, but the desire to achieve different goals than usual, to meet the needs of the customer but also to bridge the technical gap between the super technological unit and the absolute inexperience of the operator.

The main task

We all know very well that machines must be super performing, precise, reliable, and repetitive, so the technology must be avant-garde, with top quality materials.

However, no one has ever addressed the problem from the point of view of who uses these machines and works them for 8/10 hours a day. The operator.

It receives an important task, it has to produce as much as possible, it has no mitigating factors.

Our objective

Most of the time, it reaches a sufficient level of training, only after several years of work, with considerable expenditure of resources and energy on the part of the company.

Here is the goal, to find something that could meet the needs of the customer and help the operator in his daily tasks, lifting him from certain responsibilities, making him more confident while working.

We focused our studies, tests, and developments on finding something that would make machines more easily usable by operators.

Our achievements

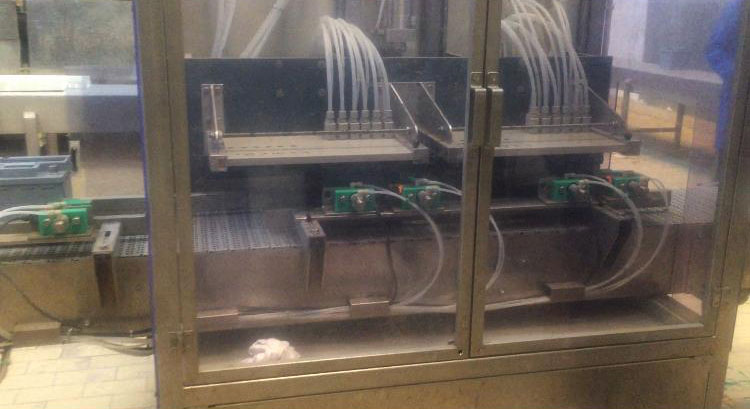

The masks system

making a start

And what could be more challenging, delicate, important, and productive than simplifying format changes? Moving from processing an L2 to processing a type B, per example.

LC Automations has achieved the objective

“No more ifs or maybes”

LC Automazioni